Борона шлейфова Green Way 7 м

Борона шлейфова Green Way 7 м

- ромбічний зуб аналог МакФарлейн

- потужність трактора від 120 к.с.

- 16 рядів шлейфів

- 6 положень кутів атаки

звертатися за телефоном:

Рекомендації:

Шлейфова борона Green Way 7 метрів — ідеальний вибір для фермера!

Якщо у вашому господарстві є трактор потужністю від 120 кінських сил, шлейфова борона Green Way 7 метри стане незамінним інструментом для обробки ґрунту.

Робочий орган шлейфової борони Green Way 7 метрів

Зуби з високоміцної сталі

Робочий орган шлейфової борони Green Way 7 метрів оснащений зубами з ножевидним (ромбічним) перетином, виготовленими з високоміцної сталі 60С2А. Ромбічний перетин зуба у порівнянні зі стандартним квадратним дозволяє знизити навантаження на тягове зусилля трактора до 20%. Це забезпечує ефективну роботу з тракторами потужністю від 72 до 400 к.с., при агрегатуванні зі шлейфовими боронами Green Way шириною захвату від 4,3 до 24 м.

Оптимальна кількість зубів

Зуби розташовані з розрахунку 70 зубів на 1 м захвату, що гарантує рівномірне та ефективне оброблення ґрунту навіть на великих площах.

Шлейфова конструкція

Зуби закріплені на поперечних тягах, шарнірно з'єднаних у 16-рядів шлейф. Це дозволяє точно копіювати рельєф місцевості під час обробки, забезпечуючи високу якість виконання обробки ґрунту.

Конструкція та зручність транспортування

Компактна рама

Шлейфова борона Green Way 7 метрів змонтована на компактній рамі з високоякісного профільного прокату, що дозволяє легко транспортувати агрегат з поля на поле без необхідності додаткового супроводу.

Гідравліка

Оснащена гідравлікою, борона дозволяє протягом 3-5 хвилин переводити агрегат з транспортного положення в робоче та назад, що підвищує ефективність роботи та зручність використання.

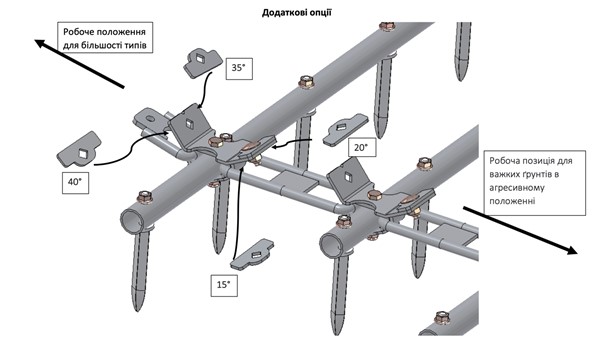

Додаткові опції для важких ґрунтів

Важкі секції шлейфової борони (+10 к.с.)

При використанні на важких ґрунтах доступна опція важких шлейфів з посиленими зубами, які встановлюються за колесами трактора. Це забезпечує максимальне переущільнення ґрунту та підвищує якість обробки.

4 додаткові регулювання кута атаки зубів за допомогою комплекту шайб

Гнучкість у використанні

Рекомендується використовувати 16-рядівний шлейф для досягнення максимальної якості роботи борони. Кожен 16-рядівний шлейф складається з двох частин по 8 рядків, які можна встановлювати окремо за потреби, наприклад, при надмірній засміченості поля або недостатній потужності тягача.

Переваги шлейфової борони Green Way 7 метрів від «Аверс-Агро»:

- Ефективність: Зниження навантаження на трактор дозволяє використовувати борону з меншими витратами палива та ресурсів.

- Довговічність: Високоміцні матеріали забезпечують тривалий термін служби навіть при інтенсивній експлуатації. Зуби борони створені з високоміцної сталі 60С2А, що забезпечує їх тривалий термін служби навіть при інтенсивній експлуатації. Рами всіх моделей шлейфової борони Green Way виготовлені з безшовної труби зі сталі 09Г2С.

- Універсальність: є заміною багатьох передпосівних агрегатів.

- Зручність використання: Швидкий перехід між транспортним та робочим положенням завдяки гідроприводам.

Обирайте надійну та ефективну шлейфову борону Green Way від «Аверс-Агро»!

Замовляйте зараз та забезпечте своєму господарству найкращі рішення для обробки ґрунту.

|

Продуктивністьпри швидкості 12км/год , га/год |

8,6 |

|

Робоча швидкість, км/год |

8-15 |

|

Транспортна швидкість, не більше, км/год |

20 |

|

Робоча ширина захвату, м |

7,2 |

|

Робоча довжина, м |

9,36 |

|

Тип агрегатування |

причепний |

|

Робочя глибина обробки грунту, мм |

20-80 |

|

Кількість шлейфів, м |

4 |

|

Кількість рядків у шлейфі, м |

8*2=16 |

|

Кількість зубів стандартних, шт |

480 |

|

Кількість зубів на довжині 300мм, шт |

20 |

|

Регулювання кута атаки зубів (6 положень) |

38° и 50° плюс 4 додаткових |

|

Габаритні розміри в транспортному положенні: |

|

|

довжина, м |

4,75 |

|

ширина, м |

2,8 |

|

висота, м |

3,7 |

|

Потужність трактора не менше, к.с. |

120 |

|

Мінімальна кість робочих виходів |

2 |

|

Тиск в гідросистемі, бар |

180 |

|

Маса, кг |

2120 |

Шлейфова борона Green Way 7 метрів

Призначення:

- Фінішна обробка полів після дискування чи культивації.

- Підготовка посівного ложа для посіву різних культур, таких як пшениця, ріпак, люцерна тощо.

- Знищення бур’янів у фазі білої нитки.

- Закриття вологи та видалення ґрунтової кірки.

- Рівномірне перемішування та розподіл пожнивних залишків.