Flex harrow Green Way 11 m on tandems

Flex harrow Green Way 11 m on tandems

- rhombic tooth analogue McFarLane

- tractor power from 190 hp

- 16 rows of trains

- 6 angles of attack

contact us by phone:

The Green Way 11 meter flexible harrow is the perfect choice for the farmer!

If you have a tractor with 190 horsepower or more, the Green Way 11 meter flexible harrow will be an indispensable tool for tillage.

Working unit of the Green Way 11 meter flexible harrow

High-strength steel teeth

The working unit of the Green Way 11 meter flexible harrow is equipped with knife-shaped (rhombic) teeth made of high-strength steel 60C2A. The rhombic tooth cross-section compared to the standard square tooth cross-section reduces the tractor pulling force by up to 20%. This ensures efficient operation with tractors from 72 to 400 hp, when combined with Green Way flexible harrows with working widths from 4.3 to 24 m.

Optimum number of teeth

The teeth are arranged at a rate of 70 teeth per 1 m of working area, which guarantees uniform and efficient tillage even over large areas.

Flexible design

The teeth are mounted on cross links that are articulated into a 16-row stub. This allows the teeth to precisely follow the terrain during cultivation, ensuring high quality tillage performance.

Design and ease of transportation

Compact frame

The Green Way 11 meter flexible harrow is mounted on a compact frame made of high quality rolled section steel, which allows the machine to be easily transported from field to field without the need for additional support.

Hydraulics

Equipped with hydraulics, the harrow can be moved from transport to working position and back again within 3-5 minutes, which increases efficiency and ease of use.

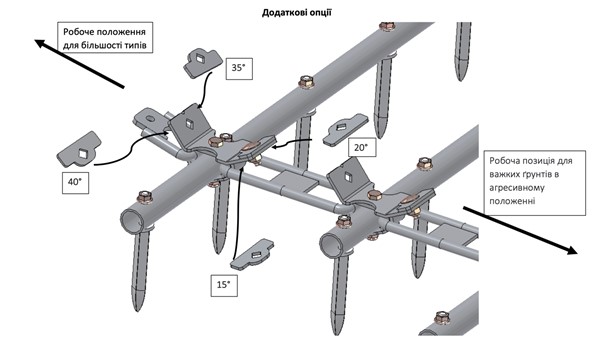

Additional options for heavy soils

Heavy duty harrow sections (+10 hp)

When used on heavy soils, the option of heavy harrow sections with reinforced teeth, which are mounted behind the tractor wheels, is available. This ensures maximum reconsolidation of the soil and improves cultivation quality.

4 additional teeth attack angle adjustments with washer set

Flexibility in use

It is recommended to use a 16-row train to maximize the harrow's performance. Each 16-row train consists of two parts of 8 rows, which can be installed separately if necessary, e.g. if the field is too clogged or the tractor is underpowered.

Advantages of the Green Way 11-meter flexible harrow from Avers-Agro:

- Efficiency: Reduced tractor load allows the harrow to be used with less fuel and resources.

- Durability: Highly durable materials ensure a long service life even under intensive use. The harrow teeth are made of high-strength 60C2A steel, which ensures a long service life even under intensive use. The frames of all Green Way flexible harrow models are made of seamless 09Г2С steel tubing.

- Versatility: Replaces many seedbed preparation machines.

- Ease of use: Quick changeover between transport and working position thanks to hydraulic actuators.

Choose the reliable and efficient Green Way flexible harrow from Avers-Agro!

Order now and get the best tillage solutions for your farm.

|

Indicator |

Value |

|

|

|

||

|

Working width, m: |

11,52 |

|

|

Working length, m: |

11,63 |

|

|

Length during transportation, m: |

7,15 |

|

|

Height during transportation, m: |

3,75 |

|

|

Width during transportation, m: |

3,0 |

|

|

Total weight, t: |

4,25 |

|

|

Number of stubs with teeth: |

6 |

|

|

Number of flex harrow teeth: |

768 |

|

|

Distance between teeth in a row, m: |

0,24 |

|

|

Number of rows with teeth in the flex: |

8х2=16 |

|

|

Distance between harrow single teeth, m: |

0,015 |

|

|

Depth of processing, mm: |

0-80 |

|

|

Angle adjustment of the teeth attack |

2 main position (38° and 50°) |

|

|

Tire sizes |

|

|

|

Support wheels: |

10.0/75-15.3 (14PR) |

|

|

Support wheels (optional): |

11.5/80-15.3 (14PR) |

|

|

Support wheels (optional): |

12,5/80-15.3 (14PR) |

|

|

Tire pressure, bar: |

4,0 – 5,0 |

|

|

Tractor hitch: |

Mounted KAT2 |

Mounted KAT3 |

|

Hydraulic requirement |

|

|

|

lifting/lowering |

1 double-acting spool valve |

|

|

folding |

1 double-acting spool valve |

|

|

Hydraulic system pressure, bar: |

180 |

|

|

Minimum tractive power of the tractor, h.p.: |

170 |

|

|

Recommendation for deep processing, h.p.: |

190 |

|

|

Number of attendants, people: |

1 |

|

Flexible harrow Green Way 11 meters

Purpose:

- Final cultivation of fields after disking or cultivation.

- Preparation of the seedbed for sowing various crops such as wheat, rape, alfalfa and similar.

- Destruction of weeds in the white thread phase.

- Sealing moisture and removing soil crust.

- Uniform mixing and distribution of crop residues.