Борона шлейфова Green Way 14 м

Борона шлейфова Green Way 14 м

- ромбічний зуб аналог МакФарлейн

- потужність трактора від 240 к.с.

- 16 рядів шлейфів

- 6 положень кутів атаки

звертатися за телефоном:

Рекомендації:

Шлейфова борона Green Way 14 метрів — ідеальний вибір для фермера!

Якщо у вашому господарстві є трактор потужністю від 240 кінських сил, шлейфова борона Green Way 14 метрів стане незамінним інструментом для обробки ґрунту.

Робочий орган шлейфової борони Green Way 14 метрів

Зуби з високоміцної сталі

Робочий орган шлейфової борони Green Way 14 метрів оснащений зубами з ножевидним (ромбічним) перетином, виготовленими з високоміцної сталі 60С2А. Ромбічний перетин зуба у порівнянні зі стандартним квадратним дозволяє знизити навантаження на тягове зусилля трактора до 20%. Це забезпечує ефективну роботу з тракторами потужністю від 72 до 400 к.с., при агрегатуванні зі шлейфовими боронами Green Way шириною захвату від 4,3 до 24 м.

Оптимальна кількість зубів

Зуби розташовані з розрахунку 70 зубів на 1 м захвату, що гарантує рівномірне та ефективне оброблення ґрунту навіть на великих площах.

Шлейфова конструкція

Зуби закріплені на поперечних тягах, шарнірно з'єднаних у 16-рядів шлейф. Це дозволяє точно копіювати рельєф місцевості під час обробки, забезпечуючи високу якість виконання обробки ґрунту.

Конструкція та зручність транспортування

Компактна рама

Шлейфова борона Green Way 14 метрів змонтована на компактній рамі з високоякісного профільного прокату, що дозволяє легко транспортувати агрегат з поля на поле без необхідності додаткового супроводу.

Гідравліка

Оснащена гідравлікою, борона дозволяє протягом 3-5 хвилин переводити агрегат з транспортного положення в робоче та назад, що підвищує ефективність роботи та зручність використання.

Додаткові опції для важких ґрунтів

Важкі секції шлейфової борони (+10 к.с.)

При використанні на важких ґрунтах доступна опція важких шлейфів з посиленими зубами, які встановлюються за колесами трактора. Це забезпечує максимальне переущільнення ґрунту та підвищує якість обробки.

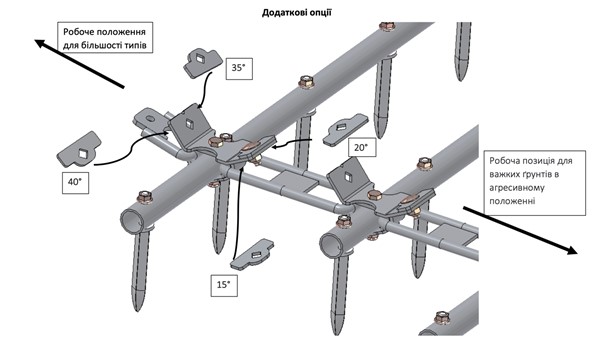

4 додаткові регулювання кута атаки зубів за допомогою комплекту шайб

Гнучкість у використанні

Рекомендується використовувати 16-рядівний шлейф для досягнення максимальної якості роботи борони. Кожен 16-рядівний шлейф складається з двох частин по 8 рядків, які можна встановлювати окремо за потреби, наприклад, при надмірній засміченості поля або недостатній потужності тягача.

Переваги шлейфової борони Green Way 14 метрів від «Аверс-Агро»:

- Ефективність: Зниження навантаження на трактор дозволяє використовувати борону з меншими витратами палива та ресурсів.

- Довговічність: Високоміцні матеріали забезпечують тривалий термін служби навіть при інтенсивній експлуатації. Зуби борони створені з високоміцної сталі 60С2А, що забезпечує їх тривалий термін служби навіть при інтенсивній експлуатації. Рами всіх моделей шлейфової борони Green Way виготовлені з безшовної труби зі сталі 09Г2С.

- Універсальність: є заміною багатьох передпосівних агрегатів.

- Зручність використання: Швидкий перехід між транспортним та робочим положенням завдяки гідроприводам.

Обирайте надійну та ефективну шлейфову борону Green Way від «Аверс-Агро»!

Замовляйте зараз та забезпечте своєму господарству найкращі рішення для обробки ґрунту.

|

Продуктивність, га/год |

17,28 |

|

Робоча швидкість, км/год |

8-15 |

|

Транспортна швидкість, не більше, км/год |

20 |

|

Робоча ширина захвату, м |

14,4 |

|

Тип агрегатування |

напівнавесной |

|

Глибина обробки ґрунту, мм |

20-80 |

|

Кількість шлейфів, шт |

8 |

|

Кількість рядів в шлейфі, шт |

8*2=16 |

|

Кількість зубів стандартних, шт |

960 |

|

Кількість зубів на довжині 300мм, шт |

20 |

|

Регулювання кута атаки зубів (6 положень) |

38°, 50° плюс 4 додаткових |

|

Габаритні розміри в транспортному положенні |

|

|

довжина, м |

9 |

|

висота, м |

4 |

|

ширина, м |

3,1 |

|

Потужність трактора, не менше к.с. |

240 |

|

Мінімальна кількість гідровиходів |

2 |

|

Тиск в гідросистемі трактора, бар |

180 |

|

Маса, кг |

5350 |

Шлейфова борона Green Way 14 метрів

Призначення:

- Фінішна обробка полів після дискування чи культивації.

- Підготовка посівного ложа для посіву різних культур, таких як пшениця, ріпак, люцерна тощо.

- Знищення бур’янів у фазі білої нитки.

- Закриття вологи та видалення ґрунтової кірки.

- Рівномірне перемішування та розподіл пожнивних залишків.