The Avers-Agro company has developed a wide model line of such units as a crop residue Roller Crimper.

This unit is produced in several versions: according to the working width, the type of aggregation, the type and diameter of the drum, the design of the knives, etc. The design features of the grinder rollers are constantly being improved, such as the frame, bearing assemblies, the system of safety cables, etc.

Roller Crimper chopping crop residues:

It is intended for crushing plant residues of sunflower, corn, legumes, cereals, green manure and weeds into organic fertilizers and evenly distributing them throughout the field. This creates a layer of mulch that prevents moisture loss, water and wind erosion, and also inhibits the growth of weeds.

Features of the use of Roller Crimper:

- The roller crimper of sunflower plant residues can be with a drum diameter of 470 mm, this diameter is quite enough to grind sunflower residues into a fraction of 5-12 cm.

- The maize crop residues roller crimper should have a more massive design with a drum diameter of 550 mm or 880 mm. The corn stalk is stiffer and denser, so the weight of a standard roller may not be sufficient.

- For guaranteed chopping of crop residues, drums with a large-diameter hollow tube, into which water is poured, can be used. Such models are called water-filled roller crimper. It is also possible to equip roller crimper with additional weights.

- Many farmers use a roller crimper as a unit for vertical processing. If you make two passes diagonally, then the soil is loosened to a depth of 5 cm, which is quite enough to sow winter crops. This method significantly reduces fuel costs and reduces the time for pre-sowing field preparation.

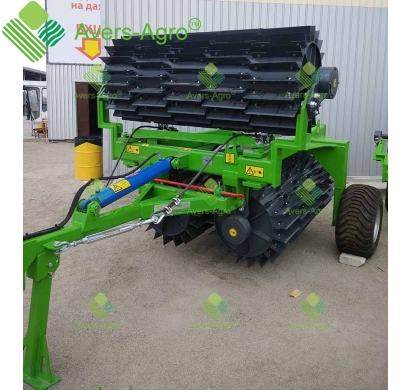

- The trailed roller crimper is equipped with transport wheels that allow you to move from field to field. The drums are equipped with special blades made of carbon steel.

Before purchasing a Roller Crimper, pay attention to its following characteristics:

- type and method of aggregation;

- performance;

- working width of capture;

- design features that are indicated in the description of the device;

- working speed;

- roller diameter;

- dimensions and weight.

- the equipment is selected specifically for the tractor: its power is necessarily taken into account, which is measured in horsepower.

Why is it better to order a Roller Crimper from Avers-Agro?

Chopping Roller Crimper from Avers-Agro have a number of advantages and proprietary developments that you will not find from other manufacturers:

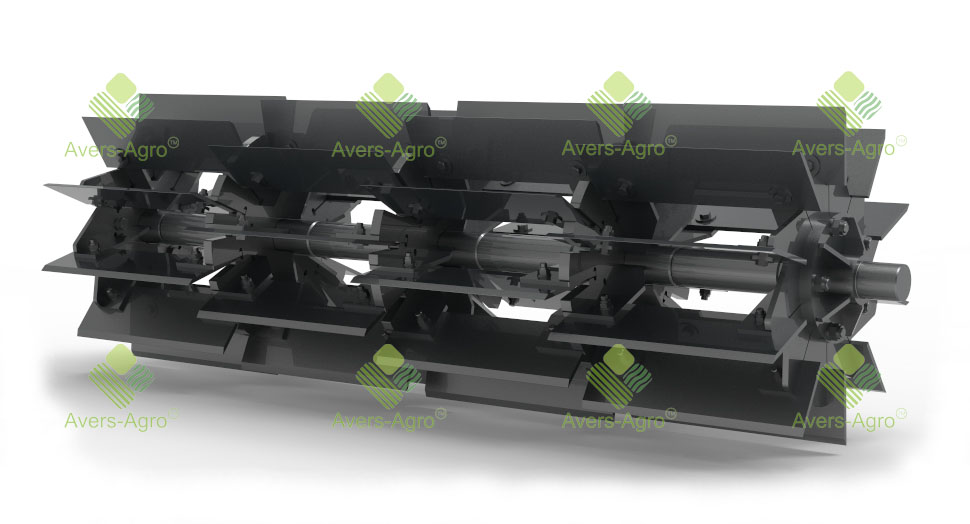

- The fan-shaped arrangement of the knives increases the load of the drum on each knife, at the same time only one knife of the drum interacts with the soil, which makes it possible to effectively chop up the crop residues. It also reduces the shock load on the bearings, allowing the roller to move more smoothly across the field and to be coupled with tractors from 60 hp.

- Floating frame. The chopper roller frame is designed in such a way that both wings work up and down. Thus, when the roller is working, the soil relief is repeated and uncultivated areas of the field will be excluded.

- Frame drum. Designed so that there is space between the knives and the shaft. Thanks to this gap, when the chopping roller is working, the earth does not wake up between the knives and the drums are self-cleaning.

- Fully collapsible drum. The drum of the grinder roller has a collapsible design, which makes it easy to repair and replace elements.

- The knives are sharpened by milling at a certain angle and have a heat-treated cutting edge, which allows you to effectively chop up crop residues and extend the service life. During work, the knives are self-sharpening.

To buy a roller crimper in the Avers-Agro company, it is enough to call our specialist at the phone number indicated on the website. You can also leave a request online. Our manager will contact you within 5 minutes and provide all the necessary advice.